โซลูชันที่กำหนดเองสำหรับการบำรุงรักษาแทร็ก

JG120LT ได้รับการออกแบบมาสำหรับงานวิศวกรรมทางรถไฟที่มีความเข้มข้นสูง หัวจับแบบเปลือกหอยเสริมความแข็งแรงใช้ระบบไฮดรอลิกที่มีความแม่นยำสูงในการควบคุมการจับยึดแบบวาล์วคู่ ซึ่งสามารถทำการคัดกรองหินรองราง การปรับแต่งลาดเอียง และการทำความสะอาดเศษหินในอุโมงค์ได้อย่างมีประสิทธิภาพในพื้นที่จำกัดความสูงของทางรถไฟ การออกแบบแชสซีตีนตะขาบที่กว้างขึ้นช่วยลดแรงกดบนพื้นดินได้อย่างมาก และด้วยระบบน้ำหนักแบบยืดหดได้ ทำให้สามารถก่อสร้างโดยไม่เกิดการทรุดตัวในพื้นที่ที่อ่อนไหว เช่น ดินอ่อนใต้พื้นและลาดเอียงของสะพาน กลไกไฮดรอลิกหมุนได้ 360° พร้อมฟังก์ชันล็อคระยะปลอดภัยหลายระดับ ช่วยให้มั่นใจได้ถึงการทำงานที่ปลอดภัยภายใต้เครือข่ายไฟฟ้า และกลายเป็นกำลังหลักอัจฉริยะของการเปลี่ยนแปลงทางรถไฟไฟฟ้า

หมายเลขสินค้า :

JG120LTสั่งซื้อ (ขั้นต่ำ) :

1การชำระเงิน :

L/C or T/Tแหล่งกำเนิดสินค้า :

Chinaสี :

yellowท่าเรือขนส่ง :

xiamenระยะเวลาดำเนินการ :

15-45daysน้ำหนัก :

12000kgรถขุดตักแบบตีนตะขาบใช้การออกแบบถังตักที่เป็นเอกลักษณ์ ทำให้สามารถขุดและขนดิน กรวด และวัสดุอื่นๆ ได้อย่างรวดเร็ว เหมาะอย่างยิ่งสำหรับงานวางรางรถไฟและงานขุดร่องน้ำ ด้วยแชสซีแบบตีนตะขาบ รถขุดนี้สามารถเคลื่อนที่ได้อย่างคล่องตัวในพื้นที่ขรุขระ เป็นโคลน หรือแคบๆ ตามแนวรางรถไฟ และจัดการกับภูมิประเทศที่ซับซ้อนใกล้รางรถไฟได้อย่างง่ายดาย การออกแบบถังตักมีความยืดหยุ่น สามารถจัดการกับงานขุดทั่วไป และยังสามารถใช้สำหรับการทำความสะอาดรางรถไฟหรือการขนส่งวัสดุ ความอเนกประสงค์ของเครื่องจักรนี้ช่วยลดต้นทุนการลงทุนด้านอุปกรณ์

ภาพรวมผลิตภัณฑ์

รถขุดรางรถไฟ JG120LT รถขุดตีนตะขาบแบบบุ้งกี๋

เพื่อรับมือกับความท้าทายด้านสภาพภูมิอากาศที่หลากหลายทั่วโลก ส่วนประกอบหลักใช้เทคโนโลยีการปิดผนึกฝุ่นระดับทะเลทรายและการอุ่นสายพานเย็นล่วงหน้า เพื่อรักษาระดับการทำงานให้คงที่ในสภาพแวดล้อมที่มีอุณหภูมิ -30℃ ถึง 50℃ ระบบปรับสภาพอัจฉริยะจะปรับความแรงในการเปิดและปิดของตัวจับยึดและความเร็วในการเดินโดยอัตโนมัติ และเพิ่มประสิทธิภาพการใช้เชื้อเพลิงให้ได้มาตรฐานอุตสาหกรรม อินเทอร์เฟซแบบโมดูลาร์ที่เปลี่ยนได้อย่างรวดเร็วช่วยให้สามารถเปลี่ยนแผ่นไฮดรอลิกหรือตัวแยกหินได้ภายในไม่กี่วินาที ตั้งแต่การก่อสร้างสาขาเหมืองในแอฟริกาไปจนถึงการเปลี่ยนที่นอนบนพื้นดินที่แข็งตัวในยุโรปเหนือ และช่วยลดระยะเวลาการก่อสร้างโครงการ EPC โดยมีอัตราความล้มเหลวต่ำกว่าค่าเฉลี่ยของอุตสาหกรรมที่ 40%

ข้อดีของผลิตภัณฑ์

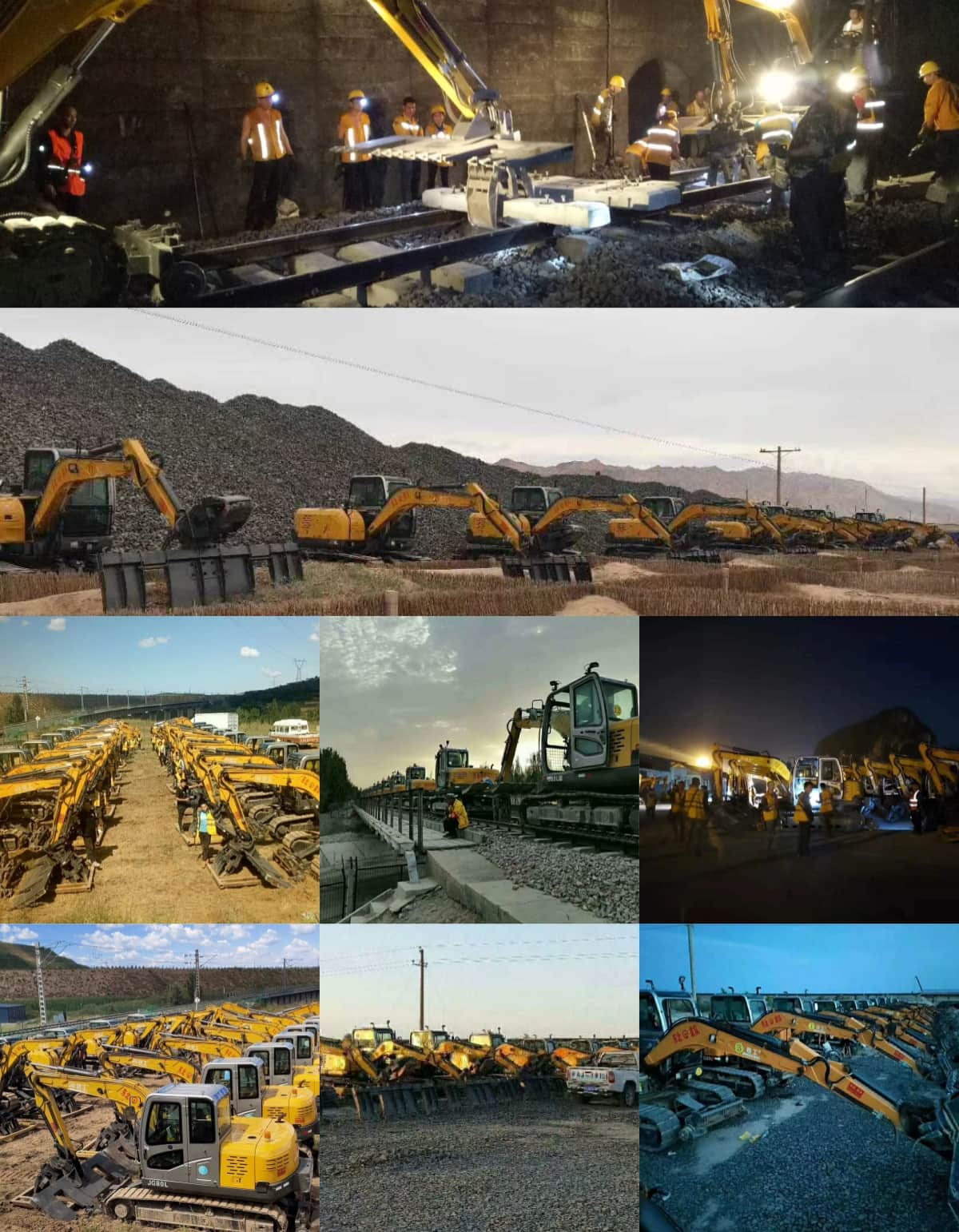

สถานการณ์การใช้งาน

นิทรรศการระดับโลก

เพื่อตอบสนองความต้องการของลูกค้าจากภูมิภาคต่างๆ บริษัทฯ เข้าร่วมงานแสดงสินค้าอุตสาหกรรมระดับนานาชาติที่มีชื่อเสียงทุกปี ผลิตภัณฑ์ของเราส่งออกไปยังกว่า 60 ประเทศและภูมิภาคในเอเชียกลาง เอเชียตะวันออกเฉียงใต้ ตะวันออกกลาง อเมริกาใต้ แอฟริกา โอเชียเนีย และอื่นๆ ปริมาณการส่งออกต่อปีสูงถึงกว่า 1,500 หน่วย และเราได้รับชื่อเสียงที่ดีในตลาดต่างประเทศ ทุกครั้งที่เข้าร่วมงาน แสดงให้เห็นถึงอิทธิพลระดับโลกของแบรนด์ เราจับมือกับพันธมิตรของเราเพื่อก้าวไปสู่อนาคตด้วยกัน!

เกี่ยวกับเรา

บริษัท Quanzhou Jingong Machinery Equipment Co., Ltd. เพียบพร้อมด้วยเครื่องจักรแปรรูปขนาดใหญ่ที่นำเข้าจากต่างประเทศหลากหลายชนิด มีนักพัฒนาด้านเทคนิคที่มีความเชี่ยวชาญ และทีมผู้บริหารที่มีความสามารถโดดเด่น ในฐานะองค์กรผลิตเครื่องจักรกลก่อสร้างระดับโลกที่บูรณาการด้านการวิจัยและพัฒนา การผลิต การขาย และบริการ บริษัทฯ มุ่งมั่นที่จะมอบเครื่องจักรกลก่อสร้างที่มีประสิทธิภาพสูงและเชื่อถือได้ รวมถึงโซลูชันอัจฉริยะแก่ลูกค้าทั่วโลก ยอดขายต่อปีสูงกว่า 30-50 ล้านดอลลาร์สหรัฐ และกำลังการผลิตรถขุดต่อปีอยู่ที่ประมาณ 2,000-3,000 คัน

ใบรับรอง

บริษัทฯ ผ่านการรับรองระบบบริหารคุณภาพ ISO9001 และการรับรองทรัพย์สินทางปัญญาแห่งชาติ และถือครองสิทธิบัตรเกือบหนึ่งร้อยฉบับ รวมถึงสิทธิบัตรสิ่งประดิษฐ์ สิทธิบัตรการออกแบบ และสิทธิบัตรแบบจำลองอรรถประโยชน์ บริษัทฯ ได้รับรางวัลต่างๆ เช่น "เครื่องหมายการค้าที่มีชื่อเสียงในประเทศ" และ "วิสาหกิจไฮเทคแห่งชาติ" และได้รับเกียรติยศมากมาย ในขณะเดียวกัน บริษัทฯ ได้รับรางวัลสิ่งประดิษฐ์ระดับนานาชาติและในประเทศหลายรางวัล และมีสิทธิ์ส่งออกได้อย่างอิสระ

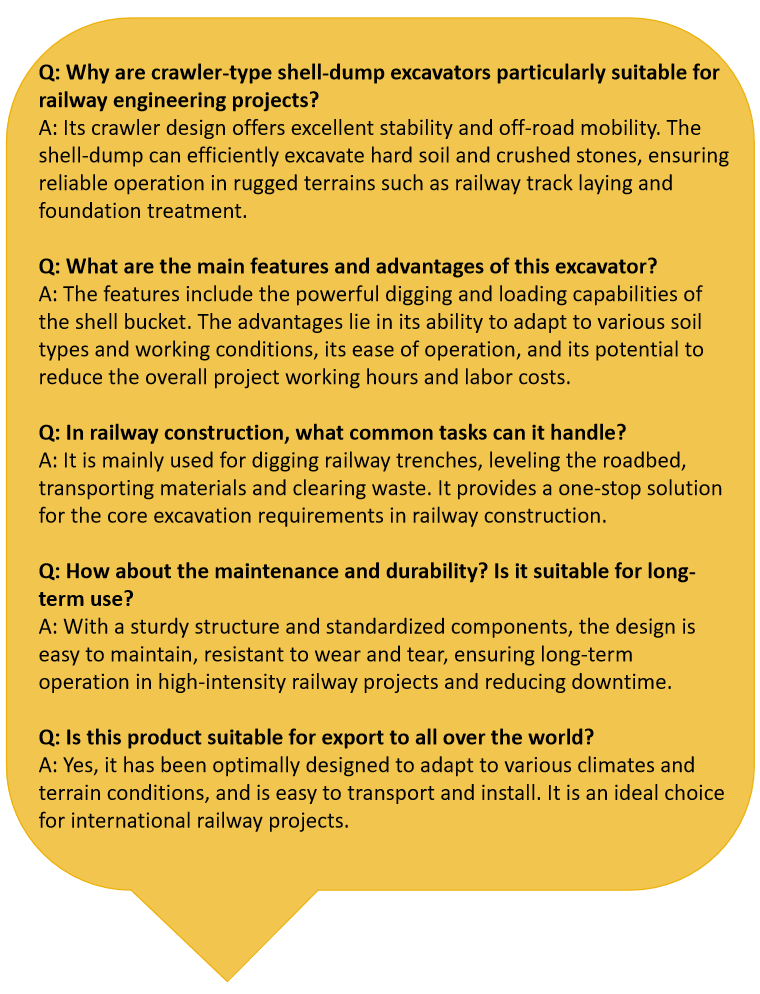

ถาม-ตอบ

เครื่องเปลี่ยนหมอนรถไฟแบบมีล้อ JG180S รถขุดรถไฟ คืออุปกรณ์ล้ำสมัยที่ออกแบบมาเฉพาะสำหรับอุตสาหกรรมก่อสร้างและบำรุงรักษาทางรถไฟ ด้วยเทคโนโลยีขั้นสูงและการออกแบบที่ทนทาน จึงมอบประสิทธิภาพและความน่าเชื่อถือที่เหนือชั้นในการเปลี่ยนหมอนรถไฟ

อ่านเพิ่มเติม

เครื่องเปลี่ยนหมอนรถไฟ JG150LT เป็นรถขุดรางตีนตะขาบที่ล้ำสมัย ถือเป็นเครื่องเปลี่ยนโฉมหน้าวงการซ่อมบำรุงรถไฟ เครื่องนี้ได้รับการออกแบบทางวิศวกรรมอย่างสมบูรณ์แบบ มอบโซลูชันที่ครอบคลุมสำหรับการดำเนินการเปลี่ยนหมอนรถไฟอย่างมีประสิทธิภาพและประสิทธิผลJG150LT ได้รับการออกแบบด้วยโครงสร้างแบบคลาน ช่วยให้รถเคลื่อนที่บนรางรถไฟได้อย่างคล่องตัว สามารถเคลื่อนที่บนทุกสภาพพื้นผิวได้อย่างคล่องตัว ทั้งพื้นผิวขรุขระและทางโค้ง ช่วยให้รถเข้าถึงทุกส่วนของเครือข่ายรถไฟได้อย่างทั่วถึง มั่นใจได้ว่างานเปลี่ยนหมอนรองรางรถไฟจะไม่หลุดลอยไปจากมือคุณ ไม่ว่าจะเป็นเส้นทางหลักระยะไกลหรือทางข้างรางระยะสั้น JG150LT ก็สามารถทำงานได้อย่างมีประสิทธิภาพ

อ่านเพิ่มเติม

เครื่องทำความสะอาดรางแบบบัลลาสต์ JG100SF โซลูชันทำความสะอาดรางแบบมืออาชีพ! ระบบคัดกรองแบบบูรณาการที่มีประสิทธิภาพสามารถขจัดสิ่งสกปรกและกรวดออกจากพื้นถนนได้อย่างรวดเร็ว และมีความสามารถในการบำบัดสูงถึง 300 ลูกบาศก์เมตร/ชั่วโมง การออกแบบแบบแยกส่วนปรับให้เข้ากับมาตรฐานสากล และการทำงานอัตโนมัติช่วยลดการลงทุนด้านแรงงานลง 70% ซึ่งช่วยปรับปรุงการระบายน้ำและเสถียรภาพของรางได้อย่างมาก เหมาะสำหรับการบำรุงรักษาทางรถไฟ รถไฟใต้ดิน และทางรถไฟความเร็วสูงที่ใช้งานหนัก โครงสร้างเหล็กที่ทนทานต่อการกัดกร่อนรับประกันอายุการใช้งานนานกว่า 10 ปี

อ่านเพิ่มเติม

รถขุดรางล้อยาง JG120S ขนาด 12 ตัน พร้อมเครื่องปรับระดับวัสดุ เป็นเครื่องจักรก่อสร้างนวัตกรรมใหม่ที่ออกแบบมาสำหรับการปรับระดับถ่านหิน รถขุดนี้ผสานรวมฟังก์ชันการทำเหมืองและการปรับระดับเข้าด้วยกัน ใช้แชสซีล้อยางขนาด 12 ตัน เพื่อการสลับการทำงานระหว่างถนนและทางรถไฟที่รวดเร็ว พร้อมระบบไฮดรอลิกที่มีประสิทธิภาพและโมดูลปรับระดับอัจฉริยะ รถขุดสามารถทำงานขุด ขึ้นรูป และปรับระดับพื้นผิวของกองถ่านหินได้อย่างแม่นยำ เพื่อให้มั่นใจว่าวัสดุจะถูกกระจายอย่างสม่ำเสมอและมีประสิทธิภาพในการบำรุงรักษาราง ตัวเครื่องมีขนาดกะทัดรัดและทนทาน เหมาะสำหรับสภาพการทำงานที่ซับซ้อนในเหมืองถ่านหิน ลานขนส่งสินค้าทางรถไฟ และสถานีอุตสาหกรรม ประสิทธิภาพการทำงานเพิ่มขึ้นมากกว่า 25% เมื่อเทียบกับเครื่องจักรแบบดั้งเดิม พร้อมลดภาระงานและค่าใช้จ่ายในการดำเนินงาน เหมาะอย่างยิ่งสำหรับการจัดการวัสดุและการบำรุงรักษารางสมัยใหม่

อ่านเพิ่มเติม

JG80LT เครื่องควบคุมบัลลาสต์รถไฟ 8 ตัน และรถขุดไฮเรลออกแบบมาเป็นพิเศษเพื่อการบำรุงรักษารางอย่างมีประสิทธิภาพ พร้อมฟังก์ชันการตกแต่งหินโรยตัวและการยกเครื่องรางแบบบูรณาการ กำลังรับน้ำหนัก 8 ตันได้รับการปรับให้เข้ากับมาตรวัดมาตรฐานสากล และระบบไฮดรอลิกควบคุมการกระจายหินโรยตัวได้อย่างแม่นยำเพื่อเสริมสร้างเสถียรภาพของฐานราง กลไกแบบหลายข้อต่อช่วยให้การทำงานมีความยืดหยุ่น 360 องศา พร้อมอุปกรณ์เปลี่ยนได้ ง่ายต่อการปรับความลาดชัน หมอนรองรางเคลียร์หินโรยตัวและตำแหน่งราง สอดคล้องกับมาตรฐานความปลอดภัย ISO สามารถปรับให้เข้ากับสภาพการทำงานที่ซับซ้อน เช่น อุณหภูมิสูงและอุณหภูมิต่ำ ลดต้นทุนการบำรุงรักษาด้วยตนเองได้อย่างมาก และเพิ่มประสิทธิภาพการดำเนินงานและการบำรุงรักษาทางรถไฟได้มากกว่า 30%

อ่านเพิ่มเติม

JG150ST คืออุปกรณ์วิศวกรรมอเนกประสงค์พิเศษที่พัฒนาโดย Seiko Machinery เพื่อตอบสนองความต้องการการบำรุงรักษาและซ่อมแซมรางรถไฟที่มีประสิทธิภาพ JG150ST ผสานรวม "ความยืดหยุ่นในการเคลื่อนที่ด้วยล้อ" เข้ากับ "ความสามารถในการปรับตัวให้เข้ากับการใช้งานทั้งบนถนนและทางรถไฟ" และได้รับการออกแบบมาโดยเฉพาะสำหรับสถานการณ์ต่างๆ เช่น การเปลี่ยนหมอนรางอย่างรวดเร็ว การบำรุงรักษาราง และการก่อสร้างตามแนวเส้นทาง ด้วยน้ำหนักใช้งาน 15 ตัน จึงสร้างสมดุลระหว่างความสามารถในการปฏิบัติงานและความคล่องตัว ทำให้ JG150ST เป็นอุปกรณ์เชิงกลหลักในการบำรุงรักษาทางรถไฟสมัยใหม่

อ่านเพิ่มเติม

ถังคัดแยกหินโรยตัวชนิดพิเศษของรถขุดรถไฟ JG80LT ออกแบบมาเพื่อการบำรุงรักษาทางรถไฟ สามารถแยกสิ่งสกปรกและสิ่งแปลกปลอมในหินโรยตัวได้อย่างมีประสิทธิภาพ รับประกันความบริสุทธิ์ของกรวด และปรับปรุงเสถียรภาพของรางรถไฟ อุปกรณ์ติดตั้งบนรถขุดโดยตรง ใช้งานง่ายและราบรื่น ลดการแทรกแซงด้วยมือได้อย่างมาก ปรับให้เข้ากับสภาพแวดล้อมการก่อสร้างที่รุนแรงและยืดอายุการใช้งาน การผสมผสานระหว่างโครงสร้างที่แข็งแรงทนทานและการออกแบบที่ชาญฉลาดทำให้เป็นเครื่องมือที่เหมาะอย่างยิ่งสำหรับทีมงานก่อสร้างประหยัดเวลา เพิ่มประสิทธิภาพและความปลอดภัยโดยรวมในโครงการวางรางหรือปรับปรุงทางรถไฟ

อ่านเพิ่มเติม

อุปกรณ์ขุดควบคุมบัลลาสต์รางรถไฟ JG80LT เป็นเครื่องมือประสิทธิภาพสูงที่ออกแบบมาสำหรับการบำรุงรักษาทางรถไฟ สามารถปรับบัลลาสต์รางได้อย่างแม่นยำเพื่อรับประกันเสถียรภาพของรางและความปลอดภัยในการใช้งาน อุปกรณ์นี้ผสานรวมฟังก์ชันการขุดและปรับแต่ง ซึ่งมีความยืดหยุ่นและใช้งานง่าย ช่วยเพิ่มประสิทธิภาพการบำรุงรักษาทางรถไฟได้อย่างมาก โครงสร้างที่แข็งแรงทนทานสามารถปรับให้เข้ากับสภาพแวดล้อมที่รุนแรง ลดความต้องการในการบำรุงรักษา และยืดอายุการใช้งาน เหมาะสำหรับงานก่อสร้างหรือโครงการบำรุงรักษาใหม่ ช่วยให้ผู้ใช้งานสามารถปรับปรุงประสิทธิภาพของรางได้อย่างคุ้มค่าและเชื่อถือได้ นับเป็นโซลูชันที่เหมาะสมอย่างยิ่งในสาขาวิศวกรรมทางรถไฟ

อ่านเพิ่มเติม